My design business, Amber Westerman Building Design, focuses on custom homes and remodels—but in 2020, I left my desk to serve as a general contractor on my 1208-sq.-ft. superinsulated, all-electric, net-zero demonstration home. I held open houses during construction to share high performance building–related information and learn what homeowners are interested in. During the tours, I explained the systems and products I used. The following were key among my talking points.

The hot water system

For hot water, I steered clear of on-demand units after hearing about how finicky they are in areas with high levels of lime in the water supply; plumbers around here routinely toss them out after a few years. I looked into heat-pump water heaters, but they are expensive and require a large mechanical room or basement, neither of which I have. What made sense was Rheem’s 30-gal. Marathon electric-resistance water heater. The tank is lightweight, insulated with 2-1⁄2 in. of foam to R-20, and will lose only 5°F in a 24-hour period. Maintenance should be virtually nil, and the unit comes with a lifetime warranty. For plumbing fixtures, I chose EPA WaterSense–labeled products to save on both hot and cold water. The toilet uses just 1.28 gal. per flush.

HVAC details

Heating and air-conditioning are supplied by a Mitsubishi ductless air-source heat pump. The outside compressor is mounted on brackets on the north wall and the inside air handler is directly above it on the loft wall—this configuration made the line set as short and unobtrusive as possible.

I chose a single-source ductless system for economy and simplicity, knowing that there would be a temperature difference between the main room (where the air handler is located) and the bedrooms at each end of the house. Over the winter, the difference was…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

14 Comments

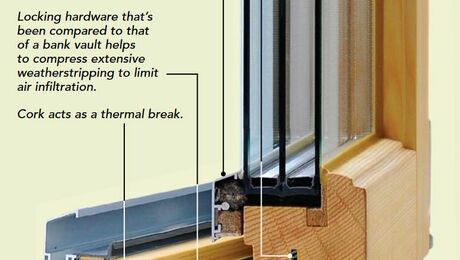

"The stock option in my region is dual-pane low-e2 glazing, which includes a second layer of low-emissivity metallic coating"

The second low-e coating actually increases condensation potential because the stock glazing options use either aluminum or stainless steel spacers. This selection forms a thermal bridge with three highly conductive surfaces. The good news is the energy loss is minimal. Keeping the house dry in the winter does help; I have the same Marvin Integrity (NKA Essential) windows in my kitchen addition in MN. They get some fogging above the sink but never frost.

"As it turns out, triple-pane windows—when amortized over 30 years—never pay for themselves. Likewise, for high-solar-gain glazing in the south-facing windows, the low-e1 glazing didn’t admit enough heat energy over the course of 30 years to make up for the upcharge. The stock option in my region is dual-pane low-e2 glazing, which includes a second layer of low-emissivity metallic coating."

I'm surprised that Marvin would upcharge for high SHGC windows. When I shopped, the high SHGC glass were double LoE180 (Cardinal branding, Guardian has similar but different naming) without the i89 on the inside pane. This was the lowest cost option. Going to LoE 272 or 366 adds an extra reflective layer, hence lower SHGC was usually more costly. The i89 was always an extra charge option. Maybe that's Marvin's standard production run for cost efficiency and they discourage special orders?

I also notice that there was only one run of 3M tape at the corners of the window rough openings. Is there a reason why the rough opening is not taped or liquid flashed as is discussed in many blogs here?

Actually good triple pane windows pay off in a big way - they are not cold when you stand or sit near them. A lot of my clients rave about that feature, and say these are the most comfortable houses they’ve ever lived in. Maybe it doesn’t pencil out, but maybe that’s not the most important metric.

I'd like to see an article in a similar vein that discusses options for low cost retrofits of smaller existing homes.

This is a harder problem because the cost/sqft of improvements is higher for smaller homes for all the usual reasons, and then even more challenging because owners of smaller homes (< 1500 sqft) tend to have less money to spend on improvments.

Improving smaller homes probably isn't as impactful in terms of CO2 emissions reduction as making the vast swath of large energy-hog homes owned by upper income people more efficient. Also, I acknowledge that the upper middle class of society (to which I belong) are the paying customer base of most green builders.

But lower income households have a much higher energy burden (energy expenditure as % of household income), so finding the right basket of efficiency improvements that such households could reasonably afford (i.e. good enough air sealing, insulation, heat pumps, and basic ERVs) would have broad socioeconomic impact.

Furthermore, those methodologies could applicable in densely populated places where even middle and upper middle income households tend to live in smaller houses.

Good points Dan, and I agree that we need to do better with the existing housing stock. I've devoted the last 35 years of my career designing remodels and additions as well as new housing but have found that energy-efficiency goals don't resonate as strongly with my remodel/addition clients as it does for those who are planning a new home. Why? I think that remodel/addition clients come to me primarily for spatial and functional solutions---they are stressed and struggling with an outdated or choppy floor plan, lack of space, mold/mildew/rot/insect/rodent problems, and are overdue for new roofing, flooring, and windows. Air-sealing and good insulation can and should be done along the way but it's simply not the same discussion I have with new home clients who have the opportunity and aspiration to think big, like maybe a net-zero energy home.

Would other articles about this house be in the works? I would be interested in the framing details of the single pitch roof, and of course insulation / air sealing. Thanks!

Ben

Hi Ben. My website http://www.poemhomes.org has a lot of pictures and fairly extensive information about my build. If you have any further questions, I'd be happy to talk with you via email or phone. There are a few framing details I'm doing differently now. For instance, framing the interior 2x4 perimeter wall after the roof is in place, not before. In either case though, the parallel chord roof trusses bear on the exterior 2x4 wall (but the profile ordered from the truss company looks different). A single pitch or shed roof isn't necessarily more or less work than a gable roof. They were set with a crane. Amber

Great floors. How did you finish them before the sealer? Just power trowel during placement?

Hi Grant. The slab really did turn out well. It was powered troweled in the usual way, then a day or so later saw cut into 10x10 areas for control joints. I waited about 6 months for the slab to cure (and crossed my fingers that no one spilled anything that would leave a permanent stain). Then I used muriatic acid to micro etch the surface so the sealer would grab. The sealer is from Ecos Paints. See my blog post “Sealing the Slab” at poemhomes.org for more details.

Dan S: RE: inexpensive retrofits: Ideally start with a Blower Door test to see how leaky your house and as important, find out where the leaks are so you can fix them. The real key to building a net zero ready house is making it tight - keeping the heat you are already making inside the house, rather than letting 30-60% of it leak out. For instance, if it's drafty near a window, there is a good chance that drafts are coming in beside the window, not through it, so remove the trim, spray in "window & door" foam that won't buckle your window but will stop the drafts & put the trim back on. The most common place in most houses is where the concrete foundation meets wood -usually leaky & you can fix that with spray foam also. These take time, but are inexpensive and make a huge difference.

Thanks Amber!

We walk past a few times when in town for APT performances or when doing improvements at Tower Hill SP. Nice job! How are you dealing with kitchen exhaust?

Dan S, Here's the link to an early build of mine that cost less than $20K (mostly recycled content).

https://www.greenbuildingadvisor.com/article/one-mans-quest-for-energy-independence-part-1

I'm looking for an old house to do a deep energy retrofit in SG but prices have been stupidly expensive.

Hi Paul. I read your 4 articles. What difficult conditions you had to achieve your goals! Congratulations on a job well done. Next time you're in Spring Green please let me know so we can meet, and I can show you around the house. Yes, there's a shortage of homes in SG and demand is high---like everywhere, we need more affordable housing. Amber

Hi Paul. I kind of cheated on the kitchen range exhaust. For esthetic reasons, I really didn't want to install a conventional range hood. Higher end options (like a downdraft or ultra-thin overhead) were out of my budget. I seldom do "messy" cooking like frying bacon, so I didn't think I'd need to capture grease, etc. If something burns or there's lots of vapor, I can turn on my Lunos HRV fans to their highest setting (for a maximum whole house ventilation of 40 cfm). This wouldn't work for the average family but so far is working for me.

I see that you're giving a workshop at the Midwest Renewable Energy Fair on your experience retrofitting your house on June 24th, 2022. I'd like to attend and meet you afterwards.

For those of you who haven't heard of it, the Energy Fair is a blast (I call it summer camp for adults). They say it's the nation's largest running event of its kind and brings in over 11,500 people. Three days of workshops, music, keynote speakers, demonstrations & tours, food, and beer.

I usually install Panasonic Whisper Light 290 cfm fans in kitchens just to clean up the air. It would be fun if you can make the fest. This show will be more about the 1926 house I did the DER on last year. GBA declined my story as it was just "too long".

Log in or become a member to post a comment.

Sign up Log in