If you’ve ever shopped for windows in the U.S., you’ve probably noticed that most windows come with a National Fenestration Rating Council (NFRC) label listing energy performance numbers. Before the NFRC developed a standardized method of reporting U-factor and solar heat gain coefficient (SHGC) ratings for windows, manufacturers’ reporting methods were inconsistent. The establishment of the NFRC standard benefited window buyers by allowing for comparison shopping.

As long as windows have an NFRC label—most major U.S. brands do—window buyers can compare the performance specifications of windows from different manufacturers. (For more information on U-factor and solar heat gain coefficient, see “All About Glazing Options.”)

Europe is different

Unsurprisingly, European window manufacturers test their windows according to different standards than American manufacturers. That means buyers can’t directly compare window performance claims made by European manufacturers to the claims of U.S. manufacturers—unless the European manufacturer has gone to the trouble of getting NFRC labels for their windows. (Most haven’t, because getting the laboratory testing done to obtain NFRC certification is expensive.)

Several GBA articles and Q&A threads explain how European window manufacturers differ from U.S. window manufacturers when it comes to reporting U-factors and solar heat gain coefficient. (Many of these articles are listed in the “Related Articles” sidebar at left.) I think it’s time to collect the most important information from all of these articles and Q&A threads together in one spot.

The table below attempts to summarize some of the differences between the North American approach and the European approach when it comes to window design and window energy performance reporting.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

19 Comments

Excellent overview, Martin. It's unfortunate that there is really no way to correlate the different ways of calculating the window U-factor. In Passive House software, each part of the window is input separately so it's custom-calculated but time-consuming to do so.

It must also be the case that there is a standard size window used for ratings. Do the two rating systems at least use about the same size window?

Pipfeiff,

The NFRC rating system is accurate for the window size you are purchasing. Software is used to adjust the U-factor as needed for differently sized windows. This software requires inputs of frame characteristics, the width of the frame, and the shape of the window. It uses extensive historical testing data of the performance of windows of different sizes and shapes.

Thanks, that's cool. Now if they could just validate their models to where they could provide U-factor as a function of delta-T (or at least the outside T while keeping the inside fixed) we'd be all set.

It's cool except during design if you're cutting it close on U-Factor requirements (code or otherwise) because the characteristics of each window with all its specific options isn't readily available. Turns out this window needs to be 6" narrower for structure, or that one can be enlarged now that there's a better location in the room for a TV? Either way could be a call to the manufacturer to figure out whether the spec needs to be changed to meet goals.

On balance I'm glad for the specificity, but it would be great to know there's always enough wiggle between product and spec to not sweat it so much. Since windows are inherently the thermal weak spots in any good wall, though, I don't think we'll get that. Performance will have to increase a great deal before standards stop rising to meet them.

It seems like we have sufficient computer power now that we could list windows with a climate-specific U-factor rating. You look up the window, put in your zip code, and get a rating for your situation, calculated for the center of glass from the specifics of the spacing, gas, and coatings used, and then adjusted for the framing.

As best I can tell from working with the manufacturers, the trick is really data entry and management for a product that has so many variables in each instance. beyond the obvious like double or triple glazing, changing the gas or coating or true lites in any window of a given size changes the whole rating. Multiply that over the material and cladding options, and the stock sizes, and the scale of data management comes into focus - then add custom sizing to the mix!

Excellent article that covers all the important points.

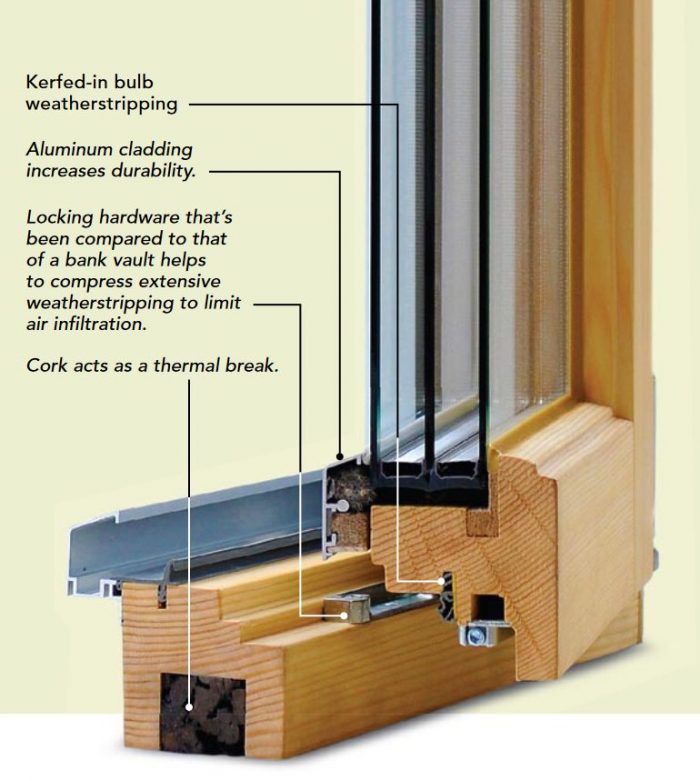

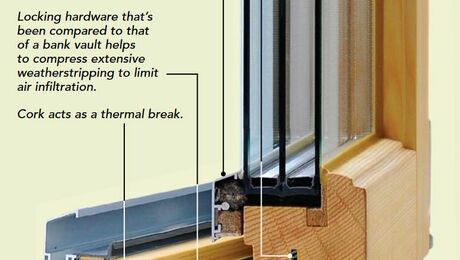

I'll just mention, I'm an American, living in France. The window in the illustration I would characterize as better than average for what is installed in the new homes here. Like in the USA, there are plenty of builders ready to put in the lowest quality they can get away with that looks good on the surface. That's why it's so important that we have a regulatory authority to set a minimum standard. Unfortunately, minimum standard is the best an uninformed homebuyer can expect to get when buying a new home.

Very helpful article and collection of other similar article links on this topic. Thanks, Martin.

Is there any source of air tightness measurements for comparing North American to European windows? Since the dogma generally prioritizes air control layer over thermal control layer, I’m wondering if air tightness should be used when selecting windows. Or, maybe manufacturers targeting high performance building have all figured out air tightness equally well that it’s a moot point? I’m assuming this article is not aimed at comparing Andersen/Marvin/Pella windows with PHI-certified European made windows.

Entropic,

For information on airtightness testing of U.S. windows, see this thread in the Q&A section: "Window NFRC ratings and airtightness."

I invite GBA readers who are familiar with European test protocols for windows to comment on how air leakage testing and reporting is done in Europe.

You can buy European (Smartwin) windows made in the Kansas from Advantage Architectural Woodwork. No relation to the company other than buying some windows from them last year, but they do good work.

Sukhoi,

Your comment raises many questions.

1. If Advantage Architectural Woodwork windows are made in Kansas, what makes the windows "European"?

2. I wonder whether Advantage Architectural Woodwork has gone to the trouble of getting NFRC labels for their windows. I see no mention of NFRC ratings on the company's web site.

I've never understood why window manufacturers use 'U' value and not 'R' value. I've never been given a good answer for this. Wouldn't it be more consistent to keep everything as an 'R' value?

Nathan,

U-factor is a technically useful factor -- literally a factor that can be multiplied in certain heat loss calculations. It predates the invention of R-value, which is a marketing term, not a technical term.

Engineers all prefer U-factor, but insulation manufacturers wanted to invent a number that worked in a "bigger is better" manner. They promoted R-value -- the inverse of U-factor -- so that American shoppers wouldn't have to deal with the "lower numbers are better" confusion.

More information is available here: "All About U-Factor."

During the development of the NFRC label, certain window manufacturers were embarrassed that they were selling R-2 or R-3 windows while fiberglass manufacturers were selling R-13 or R-26 batts. The number was small. To avoid comparison with walls, which perform better, they stuck with U-factor.

In America, it's all about marketing.

That's the first response I've heard that makes sense. I guess the lower score with golfing is a rarity ; )

Martin,

Ever tried to convince a customer 24 gauge flashing was better than 29? It may have been marketing, or maybe it was just an acknowledgment of how slow the average consumer is.

Would be interesting to know recommendations for windows in cooling-dominated regions. We have hot summers frequently exceeding 100 degrees F, and our winters rarely get below 30 degrees F. Do the same guidelines apply? Most of the year we are more interested in blocking rather than absorbing solar radiation. Is Low-E glass enough or should we be looking for more?

D. Burgoyne,

Low-e glass can either have a low solar heat gain coefficient (SHGC) or a high solar heat gain coefficient. You're looking for a window with a low SHGC, so low-e is no guarantee for your climate.

For more information, see "All About Glazing Options."

A couple other items of which to be aware: We did a project in Ohio with European windows that did not have an NFRC rating. The Plans examiner would not accept any calculations for the energy code compliance using converted European U Values, which I understand for the reasons in the article. We had to use code default U values of .55 for our triple pane windows. (This is the default for double pane, there is no code default for triple pane.) We were still able to pass the energy code, because the overall U of the envelope was still ok. There are some European manufacturers that have gone through the NFRC process, I think it is worth it to use one of them. Secondly, many European windows do not come with an etched safety glazing mark. This can also be an item of contention for inspectors and examiners. Make sure to get backup information from the manufacturer regarding the safety testing performed. Often, European safety windows are laminated rather than tempered, which is actually safer in my opinion, but many inspectors are only used to seeing tempered units and take some convincing to accept laminated.

Log in or become a member to post a comment.

Sign up Log in