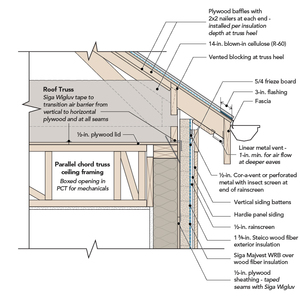

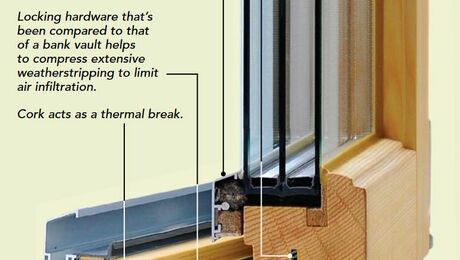

There are many construction methods and materials designed to make a home close to airtight. Their success depends on continuity of the air barrier that separates conditioned spaces from those outside the building envelope. Continuity is easily achieved when there’s nothing penetrating the air barrier. But there are occasions when plumbing, electrical, and/or ductwork systems end up outside the building. For example, forced-air heating and cooling ducts that leave the conditioned space because there was no space to keep them inside the house. The solution to this problem is to integrate a service cavity.

A service cavity is an intentional space between the finished side of a wall, ceiling, or floor and the air barrier. This space or cavity is designed to contain mechanical, electrical, and plumbing (MEP) systems. The service cavity might be large enough to house heating and cooling ducts, or small, to hide electrical wires.

Air barrier continuity

The easiest way to keep MEP systems inside the building envelope is to make the exterior sheathing on the walls and roof, along with whatever system is used for the floor, the primary air barrier (see Joe Lstiburek’s Perfect Wall). Building this way makes the entire structure a service cavity. This is a great way to build but there may be instances when you can’t—or don’t want to—use the exterior sheathing as the air barrier (for example, my recent Barndominium project did not have structural sheathing).

Most homes in my cold climate combine air and vapor control in one layer. This strategy often uses a membrane attached to the “warm-in-winter” side of an exterior wall or ceiling. (This assembly can include an interior vapor barrier and should not be used in hot-humid climates.) Traditionally, the structure is framed and installation of the…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

4 Comments

Great overview. My only caveat would be to think through what will actually be in the service cavity before deciding it is necessary - or necessary everywhere in the house. Often exterior walls or ceilings only contain one or two penetrations for electrical boxes, which are easily sealed and don't warrant the time and space necessary to create a cavity for them.

One service cavity I've found useful is to run waterlines in 3" or 4" PVC pipe under slabs., which makes modifications and replacement a lot easier.

Those trusses look nice. I can see the benefit of a central trunk running through the house like that.

Kyle,

Here is another GBA article on plenum trusses:

https://www.greenbuildingadvisor.com/article/use-plenum-trusses-to-keep-ducts-out-of-your-attic

Stephen Sheehy used a variant in which scissor trusses give sloped ceilings in most areas, but some service rooms have flat ceilings, which form service cavities.

https://www.greenbuildingadvisor.com/article/windows-and-floors-at-a-pretty-good-house-in-maine

I installed a 2x3 wall service cavity (would use 2x4 if re-doing it) and used 1x4 strapping in the ceiling in the house I'm building. My local inspector had never seen either, in all of the thousands of homes he'd inspected!

The 2x3 wall cavity was straightforward enough as he just treated it the same as any standard 2x4 wall. The strapping did require some discussion, especially related to the electrical and pex. I kept the sensitive bits away from the strapping enough that he concluded that it was very unlikely that a drywaller would miss the strapping and screw through the wire/pipe, and so he passed it.

But yeah, there is no existing standard for anything of the sort here in the Phoenix, AZ area so every use is going to be case-by-case.

Log in or become a member to post a comment.

Sign up Log in